«indium kaufen Corporation was the primary company to find a practical use for indium in the 1930s, and that was for bearing lubricants in aircraft. It was utilized in solders and fusible alloys,» Lasky explains. «Today, one of the extra attention-grabbing functions is that indium can be used as a superconductor, and it has a excessive nuclear cross-part for neutrons, so it is typically utilized in nuclear management rods.»

Extinguishing media

Suitable extinguishing agents

Special powder for steel fires. Do not use water.

For safety causes unsuitable extinguishing agents

Water

Particular hazards arising from the substance or mixture

If this product is concerned in a fire, the next will be released:

Indium oxide

Advice for firefighters

Protective gear:

No special measures required.

Thus, Indium Tin Oxide is a vital compound mainly used to make transparent and conductive coatings at the same time for screens. It is used in the making of liquid crystals, flat screens, plasma screens, touch screens, electronic ink functions, natural diodes, gentle-emitting diodes, photovoltaic cells, antistatic coatings, electromagnetic interference shields and way more.

Thus, the protocol employed by Knochel proceeds beneath situations successfully without anticaking agent, as a result of the pretreatment step would have eliminated it even when it had been present in the original pattern. This reported procedure seems to distinction with the strategies reported by Minehan and Yoshikai, in which optimal yields have been obtained in the presence of anticaking agent. It therefore seems plausible that pretreatment steps within the Knochel protocol may additionally take away an indium oxide or carbonate layer in a step unrelated to anticaking agent. Such roles for pretreatment steps separate from anticaking agent stay speculative and will not be addressed instantly with our current research.

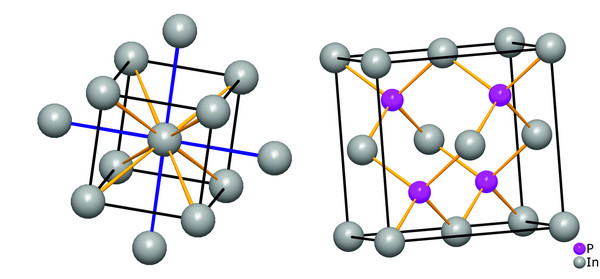

In a current examine published in Chemical Science, scientists from Waseda College and ENEOS Corporation in Japan have revealed that a novel indium oxide modified with copper (Cu-In2O3) exhibits a document-breaking CO2 conversion price of 10 mmolh-1g-1 at comparatively modest temperatures (400-500°C), making it a frontrunner amongst oxygen storage materials required for low-temperature CO2 conversion. To raised understand this behavior, the group investigated the structural properties of Cu-In oxide together with the kinetics involved within the chemical-looping RWGS response.